First Look: Enthusiast System Architecture

November 5, 2007 | 16:24

ESA Architecture:

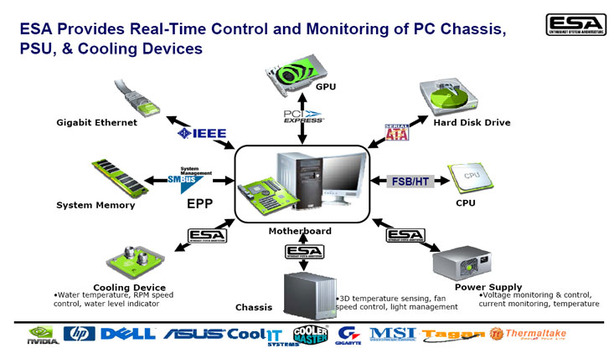

Nvidia says that the Enthusiast System Architecture will help to consolidate a wealth of information from non-standard devices via the USB interface. It does this by defining new USB HID usages for monitoring and controlling ESA-certified devices.The specification has been submitted to the USB Implementer’s Forum HID subcommittee for approval and adoption as an industry-wide standard. Given the industry support the specification has already gathered, it is quite possible that this will be adopted by the USB-IF.

One thing that was made clear to us though is that the standard will be completely open and is royalty free. If for some reason Nvidia cannot get approval from the USB-IF, company representatives have said that the specification will be made available via the Internet in much the same way that it made the EPP specification available when that first launched.

Most components have a standard interface that controls performance and stability - ESA hopes to add to this by catering for other components that don't have a standard interface.

Like EPP, there will be a certification programme, but unlike EPP, this will be handled by an independent test laboratory. Allion is a leading independent IT testing organisation based in Taiwan, and it will be responsible for handling the ESA certification process – this includes cross device compatibility and compliance with the ESA specification.

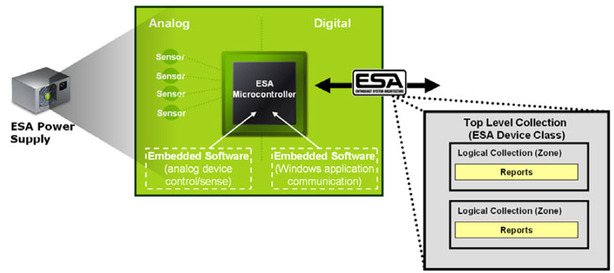

In order to meet the requirements for ESA certification, the device must implement monitoring capabilities at a bare minimum. The ESA-compliant devices will be able to communicate with the system over the USB interface using an embedded microcontroller. This microcontroller integrates a USB 2.0 compliant device controller, and is used as the primary communication channel for the information exposed by the microcontroller and, depending on the implementation, this can be monitored and controlled via a software interface.

The ESA architecture is split down into elements – these are USB HID structures that describe control/sense circuits and devices attached to the embedded ESA microcontroller. The elements have a set number of properties that help to identify the device and its capabilities – these include the following:

- String description

- Range of operation (maximum, minimum, warning points)

- XYZ position (this is most applicable to the chassis)

- Spatial zone (describes the positional relations with devices within a PC component or within devices of different PC components)

- Colour (red/green/blue) – most applicable to LEDs

- Status (functional, full/empty, etc)

A zone is a logical (or child) collection within a collection and it can help to organise sensors and controls into zones within a device – they are implemented in this way from a USB HID perspective. Data that’s recorded in each of these zones is put together in a report, and each report is given its own identification. There is no requirement for multiple zones, but they are permitted should the manufacturer see a need for more than one zone. An example of where multiple zones make sense is inside a case, where you could split down the various parts of the chassis to get more accurate and targeted temperature monitoring.

Let’s take a power supply as an example; with ESA, you could monitor and control the voltage rails, monitor and adjust the current, the power supply’s load, monitor and adjust the fan speeds, and monitor internal and exhaust temperatures. The possibilities are almost unlimited and how much information and control made available to the user will be up to the component manufacturer – the beauty is that there’s no limit to what the manufacturer can expose to the end user, as long as there is the basic monitoring capabilities enabled.

One of the ESA-enabled power supplies we saw running only displayed the voltage rails and the power supply’s total power usage – in other words, the bare minimum required for certification – but we’re confident that you’re going to see more than just this information made available once manufacturers get a handle on how to get the most out of ESA’s potential.

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.